A wide range of sealing devices are used in various machines. Sealing devices serve the following functions: Prevent leakage of sealed lubricant from inside Prevent entry of dust and foreign matter (dirt, water, metal powder, etc.) from outside As shown in Figure 1, sealing devices come in two types: contact and non-contact. Oil seals are among the major contact type sealing devices.

What are oil seals?

A wide range of sealing devices are used in various machines.

Sealing devices serve the following functions:

Prevent leakage of sealed lubricant from inside

Prevent entry of dust and foreign matter (dirt, water, metal powder, etc.) from outside

As shown in Figure 1, sealing devices come in two types: contact and non-contact.

Oil seals are among the major contact type sealing devices.

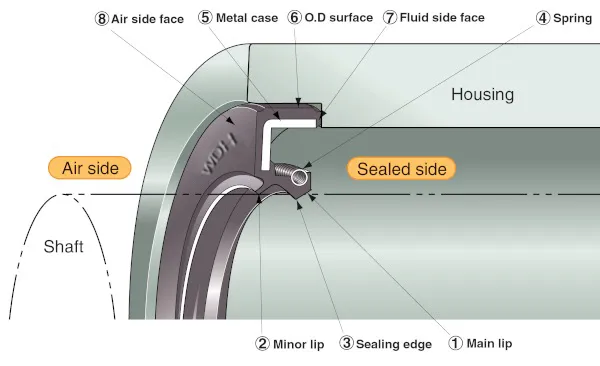

Although there are many styles of Oil Seals, they all generally consist of a flexible rubber lip bonded to a rigid metal case. Most also contain a third element – a garter spring – fitted the rubber lip to provide additional sealing force, both initially and over the life of the seal. The total radial force of the sealing lip is a function of the rubber pre-tension, coupled with the tensile spring force. The sealing lip may be lathe cut or ready molded, and may feature molded-in hydrodynamic aids to assist sealing in demanding applications. The metal case may be exposed or have rubber molded around it for ease of assembly or improved static sealing.

WDH Sealing Solutions offers state-of-the-art Oil Seal design standards based on many years of experience in a wide range of application fields.

Contact us to learn more.

Oil Seals: The structure, functions, and types of oil seals

Ø - Range | Pressure Range | Temp. Range | Velocity |

4 - 800 mm | 1 MPa | -30°C +200°C | 10 m/s |

0.157 - 31.49 in | 145 psi | -22°F +390°F | 33 ft/s |

Oil seals are widely used as sealing devices for machines.

WDH's oil seals are described in our catalog, Oil Seals & O-Rings.

However, the catalog uses a large number of technical terms and is very long, so many people seem to have trouble handling it.

Therefore, this series of columns will summarize the following in order:

• The structure, functions, and types of oil seals

• How to the right oil seal

• Handling of seals, and causes and countermeasures for oil seal failure

WDH Sealing Solutions offers state-of-the-art Oil Seal design standards based on many years of experience in a wide range of application fields.

Contact us to learn more.

EMAIL US: ADELA@WDHSEAL.COM

SKYPE: +86 156 1810 0426

THANKS/GRACIAS